This is the complete job from some quick tests. It runs perfectly fine on an Arduino based controller from a chinese DIY laser cutter kit.

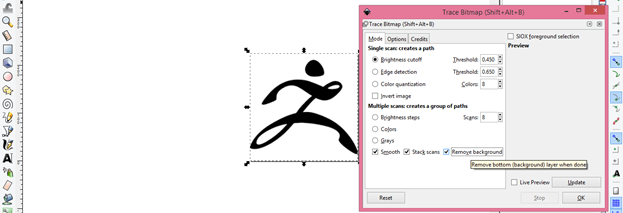

GRBL v1.1 has the new laser mode enabled. It is esspecially useful to watch the progress from other locations with access to the local network. The interface is modular and everything can be moved or disabled if not needed. It includes a hardware accelerated visualization of the gcode and laser position and allows manual jogging. For that i use CNCjs, a node.js based web server that provides a useful interface in any web browser (except Internet Explorer ). This time, put the speed to be a cutting speed (a lot slower) and use multiple passes if needed. Then, click on the cut object (like a line border) and click object to path and run the plugin again. Put the engraving laser speed for the engraving. Now the only piece that’s missing is software to stream the commands and allow control of the machine. Step 2: Open Inkscape and set up the page size to match the laser cutter bed Go to File -> Document Properties Custom size- Width 24 inches, Height 12 inches (609.6 x 304. Select the engraving object and click object to path and run the inkscape plugin. I use a special Laser cutting font because of this, named LaserCutRegular. When cutting out normal fonts some not connected parts fall out, which is normally not desired. It will output gcode that is compatible with GRBL. I use for gcode gerneration a small plugin (python script after all) from J Tech photonics, you can get the download and tutorial here.

svg, but it can also import various other formats like pdf or dxf. Inkscape is a vector graphics program, so it works normally with. Dark bright Laser Cutting: Inkscape -> CNCjs -> GRBLįor DIY laser cutters exists good open source software, this posts shows my workflow from Inscape, to creating the GCODE and finally streaming it to the machine.

0 kommentar(er)

0 kommentar(er)